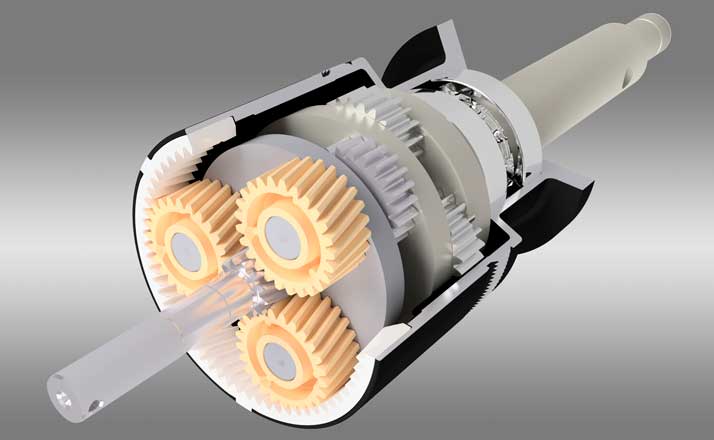

Planetary Gears GSB

The GSB line stands for high performance in combination with low backlash and high precision. Helical gears ensure a minimum noise level and smooth running. The robust, one-piece housing improves the gear rigidity and enables the absorption of high loads. The GSB line aligns economic efficiency with flexibility and is your perfect fit for a multitude of applications.

D.efinition of serial numbers

| 內部的 組號 |

類型 | 大小 | 反彈級別 | Input hollow shaft | 比率 | ||||

| 3 | – | GSB | 090 | – | 1 | – | 19 | – | 005 |

| 3 | – | GSB | 120 | – | 1 | – | 28 | – | 010 |

反彈級別: 1 = Standard; 0 = Reduced backlash

輸入空心軸直徑。= Max. motorshaft diam. = D9 in gearbox dimensions

D.imensions

| Gearbox characteristics | Stage | GSB044 | GSB062 | GSB090. | GSB120 | GSB142 | GSB180 | ||

| Centering diameter output | D.2 | h7 | 35 | 50 | 80 | 110 | 130 | 160 | |

| Output shaft diameter | D.4 | h6 | 13 | 16 | 22 | 32 | 40 | 55 | |

| Shaft height including feather key | D.5 | 15 | 18 | 24.5 | 35 | 43 | 59 | ||

| Hole circle diameter output | D.6 | 50 | 70 | 100 | 130 | 165 | 215 | ||

| Clamping system diameter | D.8 | 1 | 27 | 40 | 49 | 67. | 80 | 107 | |

| 2 | 27 | 27 | 40 | 49 | 67. | 80 | |||

| Max. motor shaft diameter | D.9 | F7 | 1 | 11 | 19 | 24 | 28 | 35 | 55 |

| 2 | 11 | 11 | 19 | 24 | 28 | 35 | |||

| 孔圓直徑輸入 | D.10 | 1 | 42 | 60..5 | 90. | 120 | 145 | 186. | |

| 2 | 42 | 42 | 60..5 | 90. | 120 | 145 | |||

| 住房長度 | L1 | 1 | 53 | 65..5 | 90. | 104.5 | 133 | 172. | |

| 2 | 79. | 87.5 | 111 | 149.5 | 171. | 217 | |||

| 軸length output | L2 | 26 | 36 | 48 | 65. | 92. | 106 | ||

| 軸length from shoulder | L3 | 20 | 28 | 36 | 50 | 74. | 82. | ||

| 以中心深度輸出 | L4 | 5 | 7 | 10 | 12 | 15 | 20 | ||

| 軸端的距離 | L5 | 2.5 | 4 | 3 | 5 | 5 | 6 | ||

| Feather key length | L6 | 15 | 20 | 30 | 40 | 65. | 70 | ||

| Max. input length motor shaft | L7 | 1 | 21 | 27.5 | 50 | 57 | 74..5 | 103 | |

| 2 | 21 | 21 | 27.5 | 50 | 57 | 74..5 | |||

| 到螺絲中心的距離 | L8 | 1 | 4.5 | 6 | 7 | 9 | 10.5 | 11 | |

| 2 | 4.5 | 4.5 | 6 | 7 | 9 | 10.5 | |||

| Flange thickness output | L11 | 5 | 8 | 10 | 12 | 15 | 16 | ||

| D.istance clamping device – housing | L13 | 1 | 11 | 15.5 | 17.5 | 25.5 | 25.5 | 34 | |

| 2 | 11 | 11 | 15.5 | 17.5 | 25.5 | 25.5 | |||

| Square housing output | SQ1 | 44 | 62. | 90. | 120 | 142 | 180. | ||

| 方形外殼輸入 | SQ2 | 1 | 44 | 62. | 90. | 120 | 142 | 180. | |

| 2 | 44 | 44 | 62. | 90. | 120 | 142 | |||

| Feather key width | B1 | h9 | 5 | 5 | 6 | 10 | 12 | 16 | |

| Min. mounting thread x depth | G2 | 4 x | 1 | M4 x 8 | M5 x 11. | M6 x 12 | M8 x 16 | M10x 20 | M12.x 24 |

| 2 | M4 x 8 | M4 x 8 | M5 x 11. | M6 x 12 | M8 x 16 | M10x 20 | |||

| Min. mounting thread x depth | G3 | M4 x 11 | M5 x 14. | M8 x 20 | M10x 23 | M12.x 28 | M14 x 32 | ||

| 孔孔 | H1 | 4 x | 4.5 | 5.5 | 6.8 | 9 | 11 | 13 | |

| Angle in ° | W1 | 45 | 45 | 45 | 45 | 45 | 45 | ||

| x times angle in ° | W2 | 4 x90. | 4 x90. | 4 x90. | 4 x90. | 4 x90. | 4 x90. | ||

| Angle in ° | W3 | 30 | 30 | 30 | 30 | 30 | 30 | ||

| x times angle in ° | W4 | 4 x90. | 4 x90. | 4 x90. | 4 x90. | 4 x90. | 4 x90. |

Find additional info tomotor flangesand減少袖子以下。

Power table

| Gearbox characteristics | GSB044 | GSB062 | GSB090. | GSB120 | GSB142 | GSB180 | Stage | |||

| 服務壽命*1 | tL | h | 30000 | |||||||

| Nominal input speed | n1 | rpm | 5000 | 5000 | 4000 | 4000 | 3000 | 3000 | ||

| Max. input speed | n1最大限度。 | rpm | 10000 | 10000 | 8000. | 8000. | 60.00 | 60.00 | ||

| Standard backlash | jt | arcmin | <= 3 (opt. <= 1) | 1 | ||||||

| <= 5 (opt. <= 3) | 2 | |||||||||

| Noise level*2 | Qg | D.B (A) | <= 56 | <= 58 | <= 60 | <= 63 | <= 65 | <= 67 | ||

| Efficiency | ƞ | % | >= 97 | 1 | ||||||

| >= 94 | 2 | |||||||||

| Protection class | IP65 | |||||||||

| Torsional rigidity | ct | Nm/arcmin | 3 | 7 | 14 | 27 | 60. | 145 | ||

| Max. radial force*3 | F2r | N | 780 | 1530. | 3250 | 6800 | 9400 | 15600 | ||

| Max. axial force*3 | F2a | N | 390 | 765 | 1625. | 3700. | 4700 | 7800 | ||

| 工作溫度 | TB | °C | -25°C - + 90°C | |||||||

| Lubrication | Synthetic grease (lifetime-lubricated) | |||||||||

| 法蘭的重量*4 | mg | kg | 0.6 | 1.28 | 3.6 | 8 | 14.3 | 28.3 | 1 | |

| 0.6 | 1.73 | 4.6 | 9.42 | 17.2 | 34.1. | 2 | ||||

| Mounting position | Any | |||||||||

| Output torques | GSB044 | GSB062 | GSB090. | GSB120 | GSB142 | GSB180 | 比率 | Stage | ||

| Nominal output torque*5 | T2N | Nm | 20 | 62. | 173. | 352 | 65.6 | 1266 | 3 | 1 |

| 17 | 54 | 153 | 315 | 583 | 1122 | 4 | 1 | |||

| 17 | 50 | 168 | 350 | 649 | 1248 | 5 | 1 | |||

| 16 | 47 | 156 | 324 | 60.2 | 1163 | 7 | 1 | |||

| 15 | 45 | 150 | 313 | 581 | 1124 | 8 | 1 | |||

| 15 | 45 | 148 | 309 | 576 | 1112 | 10 | 1 | |||

| 20 | 62. | 173. | 352 | 65.6 | 1266 | 15 | 2 | |||

| 17 | 54 | 153 | 315 | 583 | 1122 | 20 | 2 | |||

| 17 | 50 | 168 | 350 | 649 | 1248 | 25 | 2 | |||

| 16 | 47 | 159 | 327 | 612 | 1174 | 30 | 2 | |||

| 16 | 47 | 156 | 324 | 60.2 | 1163 | 35 | 2 | |||

| 17 | 50 | 168 | 350 | 649 | 1248 | 50 | 2 | |||

| 16 | 47 | 159 | 327 | 612 | 1174 | 60. | 2 | |||

| 16 | 47 | 156 | 324 | 60.2 | 1163 | 70 | 2 | |||

| 15 | 45 | 150 | 313 | 581 | 1124 | 80 | 2 | |||

| 15 | 45 | 148 | 309 | 576 | 1112 | 100 | 2 | |||

| Max. acceleration torque*6 | T2B | Nm | 36 | 112 | 311 | 63.4 | 1181 | 2279 | 3 | 1 |

| 31 | 97. | 275 | 567 | 1049 | 2020 | 4 | 1 | |||

| 31 | 90. | 302 | 63.0 | 1168 | 2246 | 5 | 1 | |||

| 29 | 85. | 281 | 583 | 1084 | 2093 | 7 | 1 | |||

| 27 | 81. | 270 | 563 | 1046 | 2023 | 8 | 1 | |||

| 27 | 81. | 266 | 556 | 1037 | 2002 | 10 | 1 | |||

| 36 | 112 | 311 | 63.4 | 1181 | 2279 | 15 | 2 | |||

| 31 | 97. | 275 | 567 | 1049 | 2020 | 20 | 2 | |||

| 31 | 90. | 302 | 63.0 | 1168 | 2246 | 25 | 2 | |||

| 29 | 85. | 286 | 589 | 1102 | 2113 | 30 | 2 | |||

| 29 | 85. | 281 | 583 | 1084 | 2093 | 35 | 2 | |||

| 31 | 90. | 302 | 63.0 | 1168 | 2246 | 50 | 2 | |||

| 29 | 85. | 286 | 589 | 1102 | 2113 | 60. | 2 | |||

| 29 | 85. | 281 | 583 | 1084 | 2093 | 70 | 2 | |||

| 27 | 81. | 270 | 563 | 1046 | 2023 | 80 | 2 | |||

| 27 | 81. | 266 | 556 | 1037 | 2002 | 100 | 2 | |||

| Emergency stop torque*7 | T2Not | Nm | 60. | 186. | 519 | 1056 | 1968年 | 3798 | 3 | 1 |

| 51 | 162 | 449 | 945 | 1749 | 3366 | 4 | 1 | |||

| 51 | 150 | 504 | 1050 | 1947年 | 3744. | 5 | 1 | |||

| 48 | 141 | 468 | 97.2 | 180.6 | 3489 | 7 | 1 | |||

| 45 | 135 | 450 | 939 | 1743 | 3372 | 8 | 1 | |||

| 45 | 135 | 444 | 92.7 | 1728 | 3336 | 10 | 1 | |||

| 60. | 186. | 519 | 1056 | 1968年 | 3798 | 15 | 2 | |||

| 51 | 162 | 459 | 945 | 1749 | 3366 | 20 | 2 | |||

| 51 | 150 | 504 | 1050 | 1947年 | 3744. | 25 | 2 | |||

| 48 | 141 | 477 | 981 | 1836年 | 3522 | 30 | 2 | |||

| 48 | 141 | 468 | 97.2 | 180.6 | 3489 | 35 | 2 | |||

| 51 | 150 | 504 | 1050 | 1947年 | 3744. | 50 | 2 | |||

| 48 | 141 | 477 | 981 | 1836年 | 3522 | 60. | 2 | |||

| 48 | 141 | 468 | 97.2 | 180.6 | 3489 | 70 | 2 | |||

| 45 | 135 | 450 | 939 | 1743 | 3372 | 80 | 2 | |||

| 45 | 135 | 444 | 92.7 | 1728 | 3336 | 100 | 2 | |||

| Mass moment of inertia | GSB044 | GSB062 | GSB090. | GSB120 | GSB142 | GSB180 | 比率 | Stage | ||

| Mass moment of inertia*8 | J1 | kgcm.2 | 0.03 | 0.16 | 0.61 | 3.25 | 9.21 | 28.98 | 3 | 1 |

| 0.03 | 0.14 | 0.48 | 2.74 | 7.54 | 23.67 | 4 | 1 | |||

| 0.03 | 0.13 | 0.47 | 2.71 | 7.42 | 23.29 | 5 | 1 | |||

| 0.03 | 0.13 | 0.45 | 2.62 | 7.14 | 22.48 | 7 | 1 | |||

| 0.03 | 0.13 | 0.44 | 2.58 | 7.07 | 22.59 | 8 | 1 | |||

| 0.03 | 0.13 | 0.44 | 2.57 | 7.03 | 22.51 | 10 | 1 | |||

| 0.03 | 0.03 | 0.14 | 0.46 | 2.63 | 7.3 | 15 | 2 | |||

| 0.03 | 0.03 | 0.14 | 0.46 | 2.63 | 7.3 | 20 | 2 | |||

| 0.03 | 0.03 | 0.14 | 0.46 | 2.63 | 7.1 | 25 | 2 | |||

| 0.03 | 0.03 | 0.14 | 0.46 | 2.43 | 7.1 | 30 | 2 | |||

| 0.03 | 0.03 | 0.14 | 0.44 | 2.43 | 7.1 | 35 | 2 | |||

| 0.03 | 0.03 | 0.14 | 0.44 | 2.43 | 6.92 | 50 | 2 | |||

| 0.03 | 0.03 | 0.14 | 0.43 | 2.39 | 6.79 | 60. | 2 | |||

| 0.03 | 0.03 | 0.14 | 0.43 | 2.39 | 6.72 | 70 | 2 | |||

| 0.03 | 0.03 | 0.14 | 0.43 | 2.39 | 6.72 | 80 | 2 | |||

| 0.03 | 0.03 | 0.14 | 0.4 | 2.39 | 6.72 | 100 | 2 | |||

* 1負載因子kA=1, n2= 100 rpm,在室溫下T = 20°C在新條件下

*2 Sound pressure level at 1m distance, measured for an input speed of 3000 rpm without load

* 3在輸出軸的中心

* 4偏差高達10%可能

* 5使用壽命:30000 h, n2=100 rpm

*每小時6最大1000周期。加速扭矩比例<總操作時間的5%

*7 Max 1000 cycles over the gear service life

*8 Related to the input shaft

Motorflanges.

-

GSB 44.

Gearbox type Centering diameter

ZHole circle

LKMax. centering depth

LZMax. motor shaft length

L螺絲型

B文章編號 GSB044 30 46 4 25 M4 3-G044-030-001 40 63. 4 25 M4 3-G044-040-002 50 70 3 25 M5 3-G044-050-002 50 70 3 30 M4 3-G044-050-004 60. 75. 4 25 M5 3-G044-060-001 -

GSB 62.

Gearbox type Centering diameter

ZHole circle

LKMax. centering depth

LZMax. motor shaft length

L螺絲型

B文章編號 GSB0621st. 30 46 5 30 M4 3-G062-030-001 50 70 5 30 M5 3-G062-050-001 50 70 5 30 M4 3-G062-050-002 50 95. 5 30 M6 3-G062-050-004 60. 75. 5 30 M6 3-G062-060-001 60. 75. 5 30 M5 3-G062-060-002 70 90. 5 40 M6 3-G062-070-102 70 90. 5 30 M5 3-G062-070-003 80 100 5 30 M6 3-G062-080-001 GSB062 2st。 30 46 4 25 M4 3-G044-030-001 40 63. 4 25 M4 3-G044-040-002 50 70 3 25 M5 3-G044-050-002 50 70 3 30 M4 3-G044-050-004 60. 75. 4 25 M5 3-G044-060-001 -

GSB 90.

Gearbox type Centering diameter

ZHole circle

LKMax. centering depth

LZMax. motor shaft length

L螺絲型

B文章編號 GSB090.1st. 70 90. 8 50 M6 3-G090-070-001 70 90. 8 50 M5 3-G090-070-002 80 100 8 50 M6 3-G090-080-001 95. 115 8 50 M8 3-G090-095-002 95. 130 8 50 M8 3-G090-095-003 95. 115 13 55 M8 3-G090-095-006 110 145 8 50 M8 3-G090-110-001 110 145 22 65. M8 3-G090-110-002 110 130 8 50 M8 3-G090-110-003 130 165 8 50 M10 3-G090-130-001 GSB090.2st. 30 46 5 30 M4 3-G062-030-001 50 70 5 30 M5 3-G062-050-001 50 70 5 30 M4 3-G062-050-002 50 95. 5 30 M6 3-G062-050-004 60. 75. 5 30 M6 3-G062-060-001 60. 75. 5 30 M5 3-G062-060-002 70 90. 5 40 M6 3-G062-070-102 70 90. 5 30 M5 3-G062-070-003 80 100 5 30 M6 3-G062-080-001 -

GSB 120.

Gearbox type Centering diameter

ZHole circle

LKMax. centering depth

LZMax. motor shaft length

L螺絲型

B文章編號 GSB120 1st. 70 90. 9 63. M6 3-G120-070-001 95. 115 9 63. M8 3-G120-095-002 110 145 9 63. M8 3-G120-110-001 110 130 9 63. M8 3-G120-110-003 110 165 9 63. M10 3-G120-110-005 130 165 9 63. M10 3-G120-130-001 GSB120 2st. 70 90. 8 50 M6 3-G090-070-001 70 90. 8 50 M5 3-G090-070-002 80 100 8 50 M6 3-G090-080-001 95. 115 8 50 M8 3-G090-095-002 95. 130 8 50 M8 3-G090-095-003 95. 115 13 55 M8 3-G090-095-006 110 145 8 50 M8 3-G090-110-001 110 145 22 65. M8 3-G090-110-002 110 130 8 50 M8 3-G090-110-003 130 165 8 50 M10 3-G090-130-001 -

GSB 142

Gearbox type Centering diameter

ZHole circle

LKMax. centering depth

LZMax. motor shaft length

L螺絲型

B文章編號 GSB142第1。 114,3 200 8 80 M12. 3-G142-114-001 180. 215 8 80 M12. 3-G142-180-001 200 235 8 80 M12. 3-G142-200-001 GSB1422st. 70 90. 9 63. M6 3-G120-070-001 95. 115 9 63. M8 3-G120-095-002 110 145 9 63. M8 3-G120-110-001 110 130 9 63. M8 3-G120-110-003 110 165 9 63. M10 3-G120-110-005 130 165 9 63. M10 3-G120-130-001 -

GSB 180

Gearbox type Centering diameter

ZHole circle

LKMax. centering depth

LZMax. motor shaft length

L螺絲型

B文章編號 GSB1801st. 114,3 200 13 115 M12. 3-G180-114-001 200 235 13 115 M12. 3-G180-200-001 GSB180 2st。 114,3 200 8 80 M12. 3-G142-114-001 180. 215 8 80 M12. 3-G142-180-001 200 235 8 80 M12. 3-G142-200-001

Reduction sleeves

減少套管序列號的定義

| 內部組號 | 類型 | 輸入空心軸直徑。D. | 電機軸直徑。D. | |||

| 3 | – | G | – | 035 | – | 028 |

| 3 | – | G | – | 011 | – | 009 |

| Gearbox 類型 |

大小 | Stages | 內部的 D.iam. D |

Motor shaft diameter d in mm | ||||||||||||||||||

| 6 | 8 | 9 | 10 | 11 | 12 | 12.7 | 14 | 16 | 19 | 22 | 24 | 28 | 32 | 35 | 38 | 42 | 48 | 55 | ||||

| GSB / GSBL. | 44 | 1/2 | 11 | ✓ | ✓ | ✓ | (✓) | |||||||||||||||

| 62. | 1 | 19 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | (✓) | |||||||||||||

| 2 | 11 | ✓ | ✓ | ✓ | (✓) | |||||||||||||||||

| 90. | 1 | 24 | ✓ | ✓ | ✓ | ✓ | (✓) | |||||||||||||||

| 2 | 19 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | (✓) | ||||||||||||||

| 120 | 1 | 28 | ✓ | ✓ | ✓ | (✓) | (✓)* | (✓)* | ||||||||||||||

| 2 | 24 | ✓ | ✓ | ✓ | ✓ | (✓) | ||||||||||||||||

| 142 | 1 | 35 | ✓ | ✓ | ✓ | (✓) | ||||||||||||||||

| 2 | 28 | ✓ | ✓ | ✓ | (✓) | (✓)* | (✓)* | |||||||||||||||

| 180. | 1 | 55 | (✓) | |||||||||||||||||||

| 2 | 35 | ✓ | ✓ | ✓ | (✓) | |||||||||||||||||

✓=可用的減少套筒;

(✓) = no reduction sleeve necessary;

(✓)* =作為專門設計的模型。還可以提供進一步的直徑。請直接與我們聯係。